Heat, Light, Logic

10 min read

Yes, why not make my own solder? If you‘re wondering how I got to this point, you can read up on the chain of events in Part 1.

Up to now I was using flux core solder intended for electronics. The flux helps the solder bond to the copper tape and makes for easier soldering. However the flux residue is a mess needing cleanup and I felt it also was the reason the patina did not work consistently.

Solder is an alloy of lead and tin. I had lots of lead in the workshop and was only missing tin. My hope was to get it on the cheap and scoured online market places. Someone was selling a pure tin candle holder for an acceptable price – I had my source of tin.

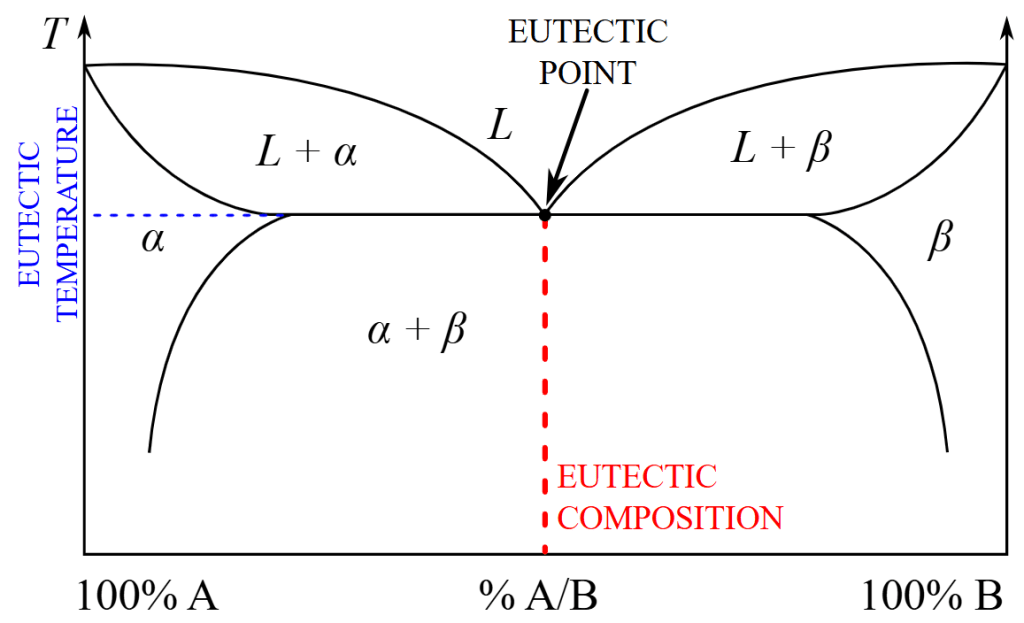

Before I show you the result, you have to endure the explanation of something truly fascinating. So you want to mix two metals – in this case lead and tin – how do you know how much of each is needed? And why would you mix them anyway? Metallurgy science has all the answers here. In most two-phase systems (aka two component metal soup) there is what‘s called a eutectic point. It represents the ratio of the two phases (metals) at which the mixture when cooling will solidify instantly without transitioning through a pasty state. Going the other way, the solid will melt directly into a liquid without chunks or pasty bits. But here is the kicker. What‘s even more interesting is that the melting point is lowest at the eutectic point out of all other mixture ratios. That means both metals in their pure form will have a higher melting point individually than when you mix them at the right ratio. This is so cool!

Bear with me just a little more while I make an example (made up numbers for simplicity). Say we have metals A and B with melting points 100° and 200°. Wouldn‘t you expect the melting point of a mixture of the two to be at 150°? Well, I would. But the eutectic temperature would be lower than 100°. So the answers to the two questions above are:

- How much of each metal goes in the mix is given by the ratio at the eutectic point.

- The reason for adjusting the ratio to the eutectic point is that the alloy will have the lowest melting point and melt without lumps/pasty phase.

Anyway, enough of that now. I had my eutectic solder.

With four terraria under my belt, I felt I was through with the simple stuff – onto new endeavours! In classic me-fashion I thought „Let’s make it complicated!“. I noticed how the little ecosystem inside would make the glass fog up if the little door was not opened the right distance. I read that Jewel Orchids actually prefer a slightly warmer climate than I had in the office or at home. I am no botanist, but clearly what the orchids needed was a terrarium with heating, climate control, sensors, full spectrum LEDs, lighting on a schedule, a real time clock, and a microcontroller to operate it all. The idea was to have an autonomous system where the only thing I would have to do was add water when the alarm goes off.

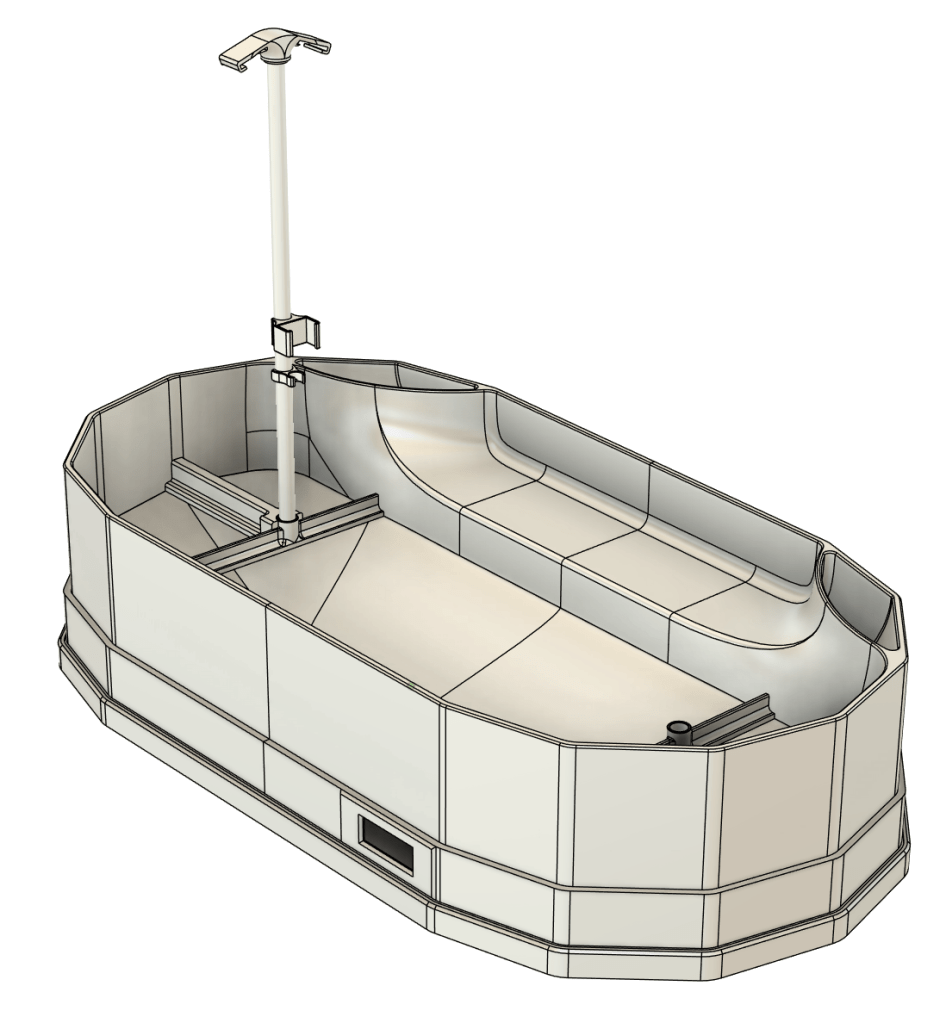

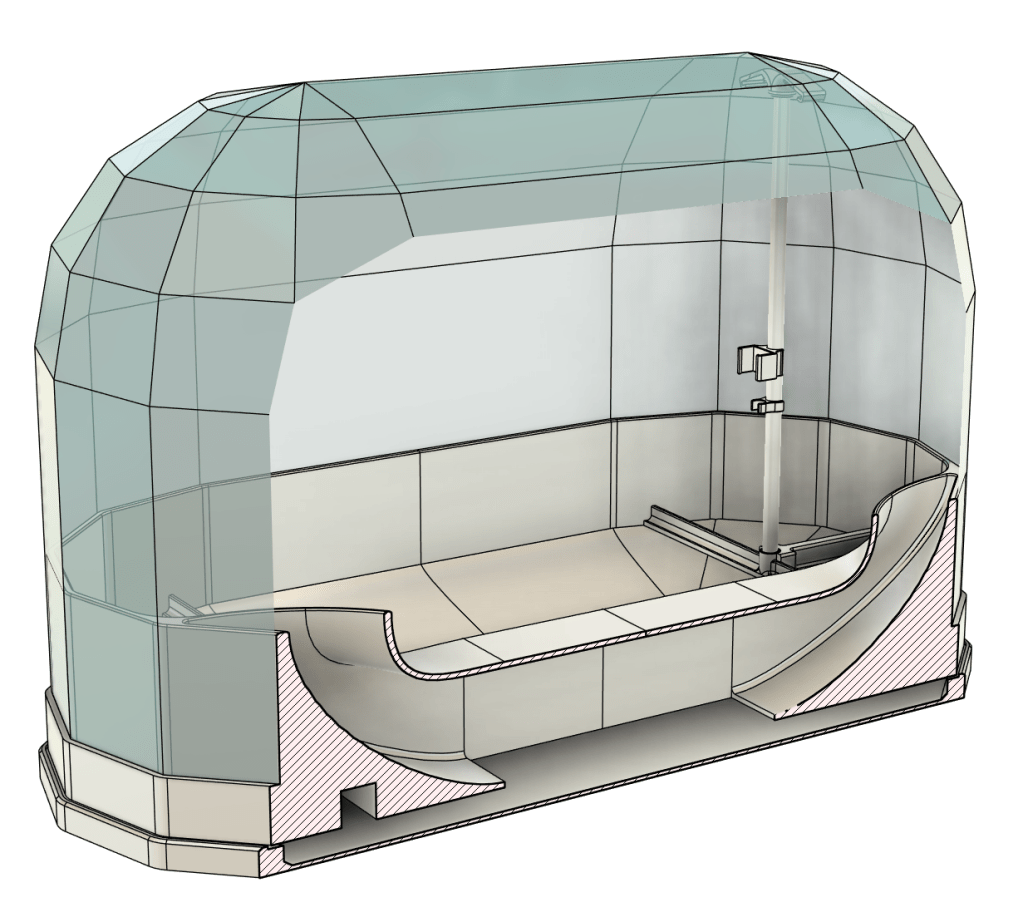

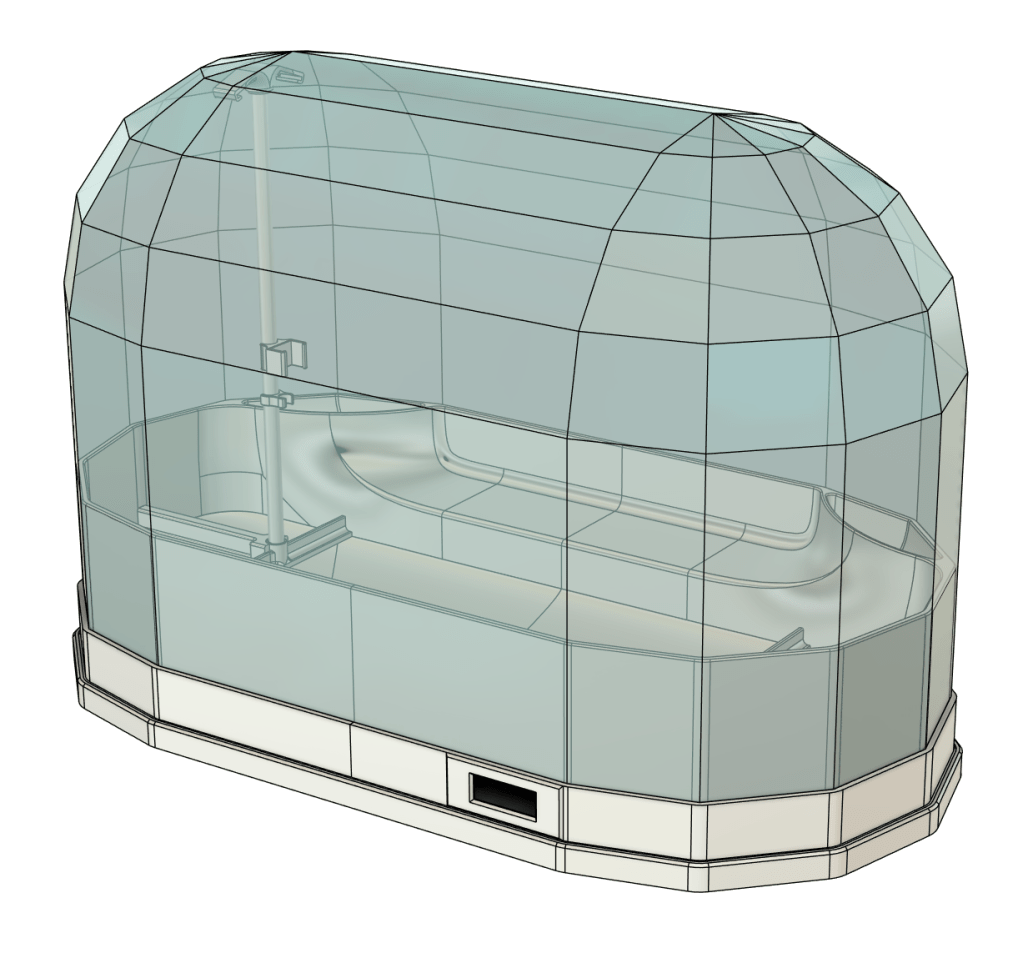

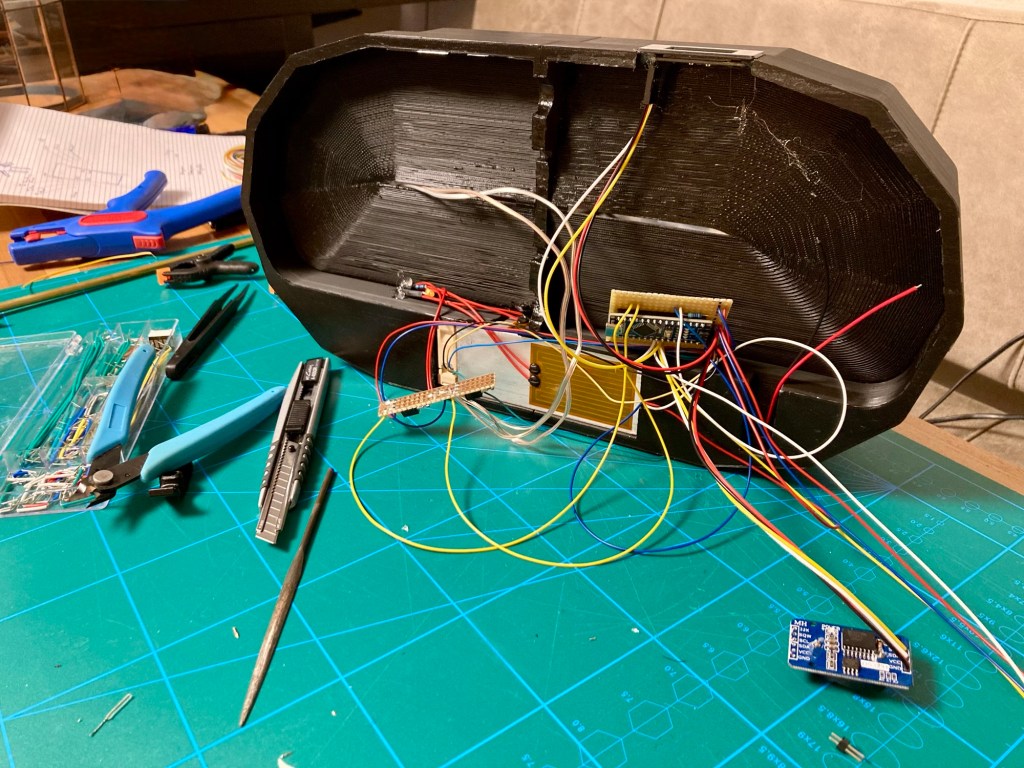

I made it a two part terrarium. The base was 3D-printed and incorporated all the fancy stuff. The top was made in the same way as the previous glass houses as far as assembly goes, but I had no pattern to go on and created my own. To this end, I modeled both top and base in CAD.

The functions of this beast:

- A heater to control the air temperature of the terrarium. Resistive heater foils heat an aluminum heatsink through which air is pushed by a fan. An attached sensor reads its temperature. The heaters‘ job is to raise air temperature to the preset level of 27° C and keep it there.

- Two independent sensors in the terrarium measure air temperature. They are the input for the temperature control loop and the higher value of the two is used.

- The reading of a humidity sensor is used as input to the dew point calculation. I wanted the controller to know the dew point and keep air temperature above to prevent condensation on the inside of the glass.

- Two strips with full spectrum LEDs to simulate sun light. This way the terrarium can be kept even in the darkest corner of the house. The controller fades out the LEDs smoothly at 10PM and turns them back on in the morning.

- An RTC (real-time clock) module keeps accurate time (microcontroller‘s internal clocks are not accurate enough for this task). The time is only needed for the lighting schedule. The other functions would be fine without it.

- A small 0.96“ OLED display to show time, heater temperature, air temperature, humidity and dew point. In addition it flashes if the humidity goes above or below a preset range.

This project had been an incredible ride and was filled with lots of enjoyable work. Naturally, I was not eager to wrap up things just yet. I had one more idea for a small decorative piece. In one of the city parks there was a statue I liked.

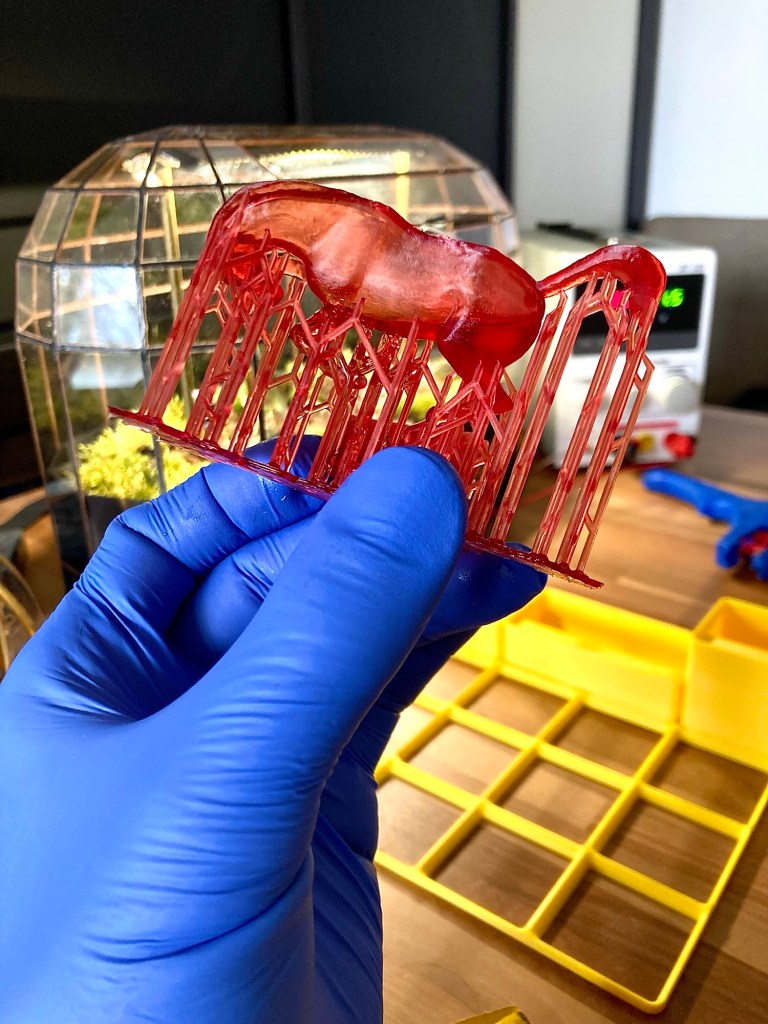

I went to scan it with a 3D-scanning app on the smartphone and created a miniature version for the terrarium. The scan required minimal cleanup in Blender – the quality coming from just a simple smartphone scan was impressive. There were some holes or spikes in the model where I could not get too close to the statue. Printing took a couple of times to get the right size, the right angle and a version where the tail did not snap off.

Challenges & Learnings

- The patina was not a simple paint job. It did not stain the solder joints evenly, I had to go over it many times. Somehow there were patches where the patina would react immediately and other areas where it would not really stain the metal. Also, I had bought two different kinds, black and copper. The copper patina was completely different to what I had expected. I was hoping for a nice copper color that I could polish but instead ended up with an ugly mix between the dull bare metal sheen of the solder itself with just a hint of copper.

- Glass cutting with a hand tool was a pain in the BUTT. It was clear after the first couple of cuts that I would not complete the project that way.

- PCBs are cheap and easy to make. Perf boards are fine for really simple and quick soldering jobs. Beyond that, making a PCB pays off very quickly.

- An interesting find was with the OLED display. At first, I programmed the microcontroller to refresh the screen every second, to keep close track of temperatures. Quite soon, maybe a couple of weeks in, I noticed how the screen started to look burnt out. The update rate had simply been way too high. I realized temperature would not change drastically from one second to the other. So I swapped out the screen for a new one and changed the refresh rate to once a minute, aligning it with the update of the time display.

- I do call a resin printer my own. Whilst I am impressed by the incredible level of detail that is achievable with the device, it is not a process I enjoy very much. It is messy and always involves a lot of cleanup. Still a great tool, I cannot complain too much.

Result

Reflections

Similar to creating notebooks, making a glass terrarium is a deeply relaxing and enjoyable process. Not quite as much as the notebooks, there are some annoying bits, like SANDING the edges. And for a complex design with many pieces it can feel repetitive and never ending. I am not complaining, every project has good and bad parts, and if I was bothered by the potential of bad parts, I would have to quit the hobby. I am merely making a comparison.

Resources

Have you tried something similar? Got tips or questions? Feel free to leave a comment below.

Leave a comment