From Rust to Revival

This project is actually a side quest from when I was making my own notebooks. Initially I was using two pieces of wood and a couple of clamps for pressing glued covers or compressing folds. It worked fine. Really, fine. I could have left it there easily… Anyway, I thought it would be nicer and more convenient to do it properly in a book press. I happened to find an antique one online and the seller even happened to be in the same city. Great! Great as well, I would find out, because the thing was HEAVY and I would not have to haul it too far.

Goal

The initial goal was simply to upgrade from clamps to book press and technically I had achieved this with the purchase. But I got the thing home and something happened which often happens: I cannot leave things be as they are (“There ought to be something I can modify here… lemmesee“). I did not like the state of it and decided to restore it and give it a nicer color in the process.

So the goal of the project became the restoration of a book press.

Materials & Tools

Materials

- Sandblasting medium

- Paint stripper

- Paint

Tools

- Sandblasting gun

- Air compressor

- Protective equipment (respirator, safety goggles, gloves)

- Paint brush

- Scraper

Process

I had never done a restoration like this before (many of my projects are firsts, I like to explore new areas, methods and tools). I knew I had to get the paint off before anything else, but the how was to be explored. I call an air compressor my own and remembered seeing compatible cheapo sandblasting guns in the hardware store for 20-30$. Hey, why not try it that way? Additional justification for this purchase was that I would have the perfect solution for surface preparation before glueing or painting. In one of his videos, laden with superb content, the charming Dan Gelbart said that sandblasting is the best way of preparing a surface for painting (he has an amazing series on prototyping, it is an absolute gold mine!). If Dan says it, it’s basically gospel to me.

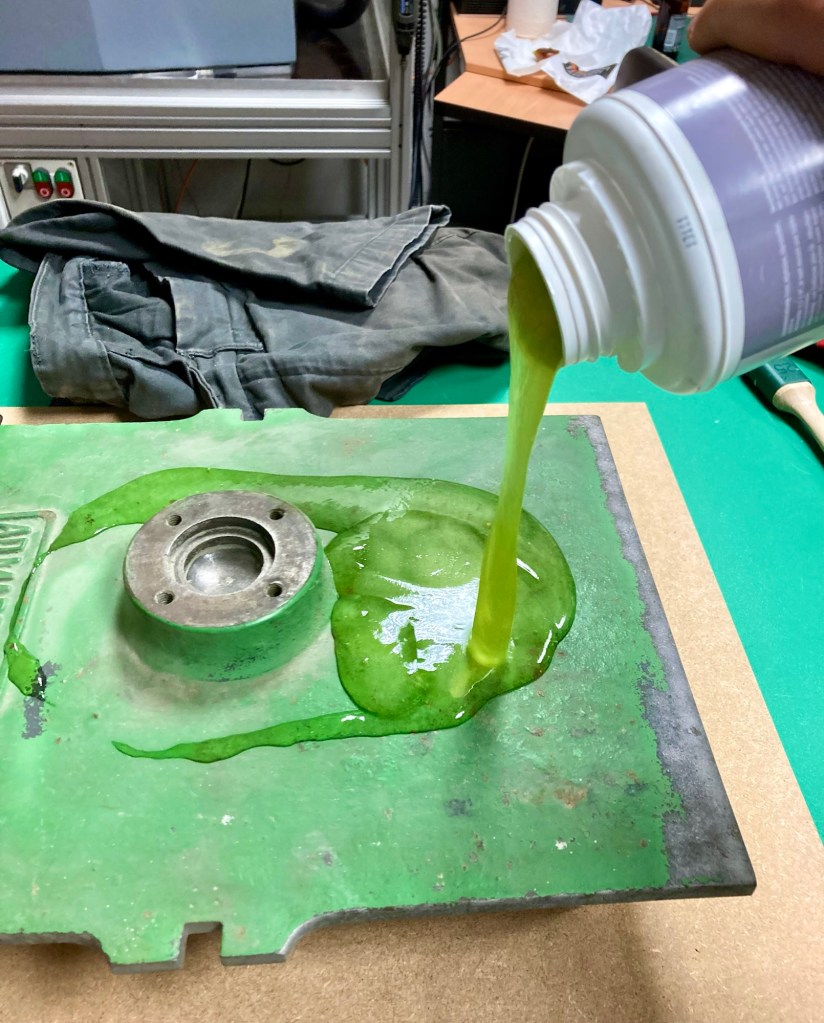

I knew sandblasting would be a mess, even more so without a dedicated cabinet. I made a makeshift sand containment by lining a small room with plastic and donning a full-body suit. The result of all that work was sadly disappointing. The compressor could not keep up with the demand of the cheap gun, and whilst I was able to get some paint off, it took way too long. Also, tons of the sand seemed to end up in my hair somehow. I abandoned that method and went to the next one: green goo. I mean paint stripper. It stinks to high heaven but works very well! The slime-like consistency helps a lot with non-level surfaces where a more runny product would drip.

Note in the center image how little progress was made while sandblasting before switching to paint stripper:) Just a small strip on the right.

With all the paint gone, some areas took more than one treatment. The first coats of paint went on. I had selected a copper paint, “Hammerschlagfarbe” (ChatGPT translates it to hammer finish paint).

Problem was, I did not like the look… So out came the goo again and another type of paint and color. This time I was happy with the result and proceeded with covering all parts.

The top and bottom press surface were bare initially and I did not want to change that. I imagined even dried paint would stick to whatever I am pressing. They were only touched up with a sander. What I wondered was how the surface should be treated in general. If it is oiled to prevent rust then you would get stains on your books and papers. If you did not oil it, you would get stains anyway but from rust this time. I guess the choice for the amateur book presser is whether he wants his stains to be oil or rust-based. However, since I planned to keep whatever I am pressing between two pieces of cardboard, I did not think about the problem any longer.

Challenges & Learnings

- Buy cheap, buy twice… I knew and heard this line many times. Because sometimes you can get away with it, it‘s hard to judge beforehand when this will be the case. For my sandblaster experiment it was definitely not true. And now I am sitting on a huge 20 kg bag of sandblasting media. To get rid of it I thought about taking a handful of the stuff in my pocket and every morning on my commute to work I‘d sprinkle some on the train, the bus and the sidewalks… (I‘m joking!).

- Not a true learning because the question is still open. How to treat the book press surfaces? To oil or not to oil.

Result

There is not a lot to say here, my workshop now has a nice and new-old book press.

Reflections

Restoration is a lot of fun. I can see myself repeating it with another ancient and worthy object.

In a way the process destroys the old version of the item and by choice of paints, techniques, what to fix and how, the restorer makes the item his very own. Should you preserve the piece as close to its original state as possible or is it okay to change and renew it for reuse in a new era?

Resources

- Dan Gelbart‘s channel on YouTube

- Dan Gelbart‘s video where he talks about surface preparation for painting and glueing

Have you tried something similar? Got tips or questions? Feel free to leave a comment below.

Leave a comment