I Could Have Used Felt Pads

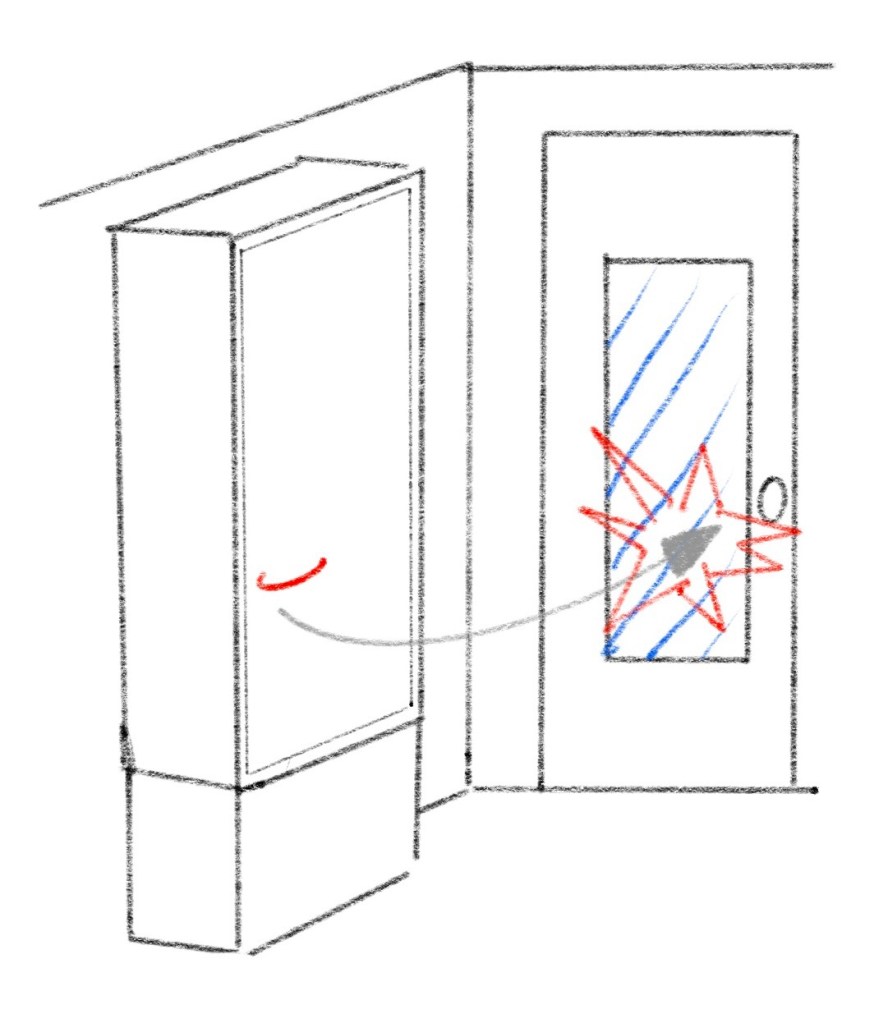

Some projects start with a problem. The problem I had here was that if I let go of the open fridge door for even a second, the metal handle would slam into the kitchen door’s glass panel. It would make this horrible sound and every time it happened I was afraid the glass would shatter.

One solution to the problem was to take the kitchen door off its hinges and put it away. No door, no crash. I did that and lived blissfully for a while. No crashes, no worries. Just the occasional aroma of garlic drifting into my living room at 10 p.m…. I needed another solution.

Goal

The aim was clear: design the most ridiculously overengineered mechanism I could—just shy of the point where it becomes another sketch lost in the black hole of “projects I never finish.” It had to be difficult enough to impress myself—yet just easy enough that I wouldn’t abandon it at the first sign of resistance. In other words: complicated, but still finishable.

Materials & Tools

- PLA filament

- 3D printer

- Whatever cool part I could find on AliExpress

- Standard assembly tools like srew driver, allen wrenches, pliers and the like

Process

The majority of the project happened at the PC. I use Fusion 360 to design all my 3D printed parts. It can be used for free as a hobbyist, and the workflow is quite nice with tools like the 3D printer or the CNC.

With the sketch ready, I started designing the mechanism (a good rule of thumb for CAD is: when you don‘t know yet what you want to design, use a sketchbook, not CAD).

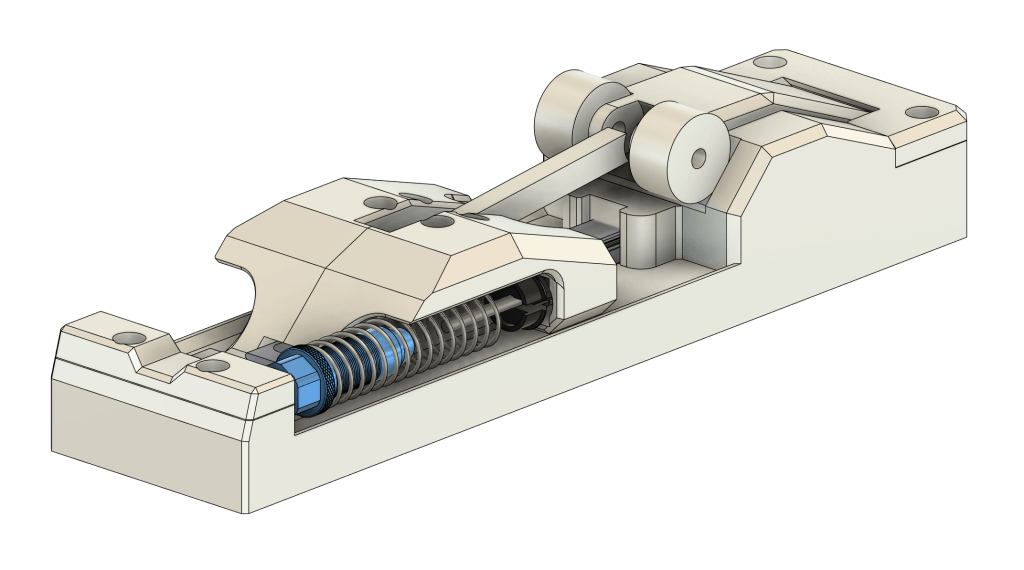

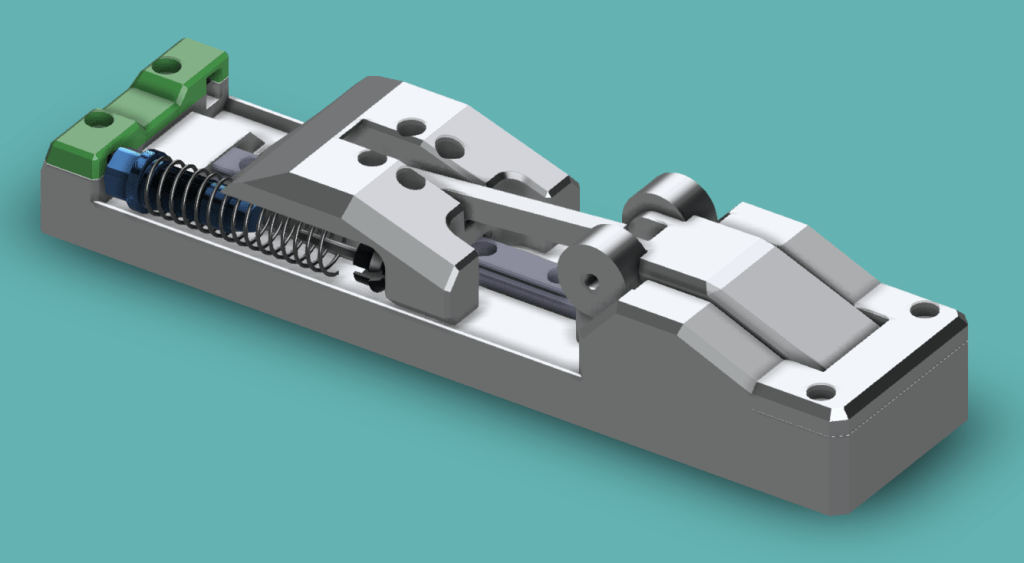

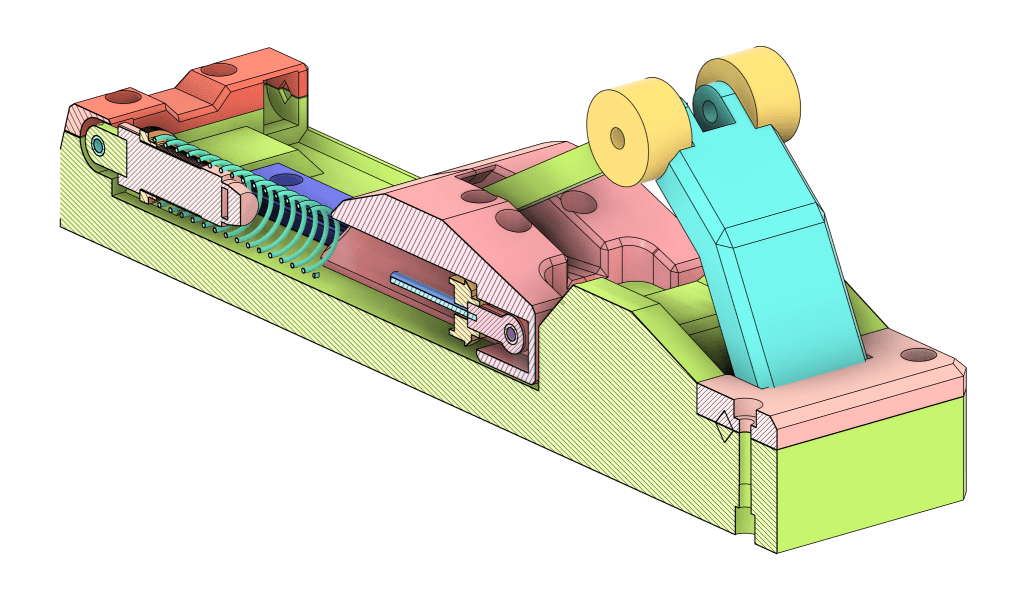

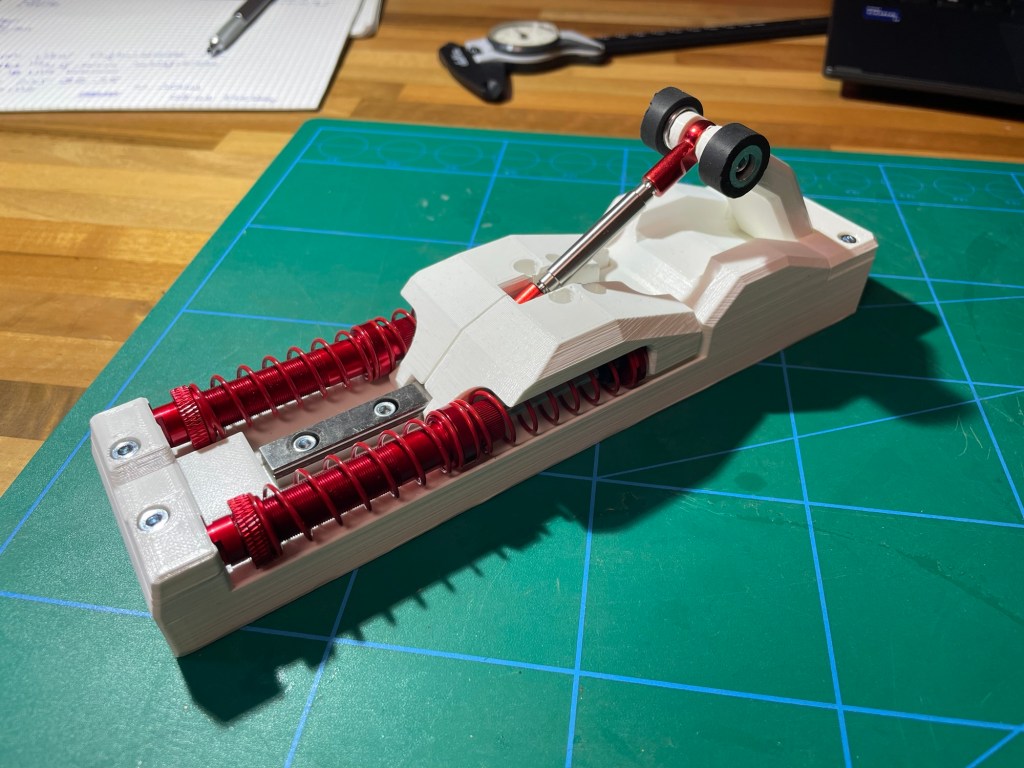

The idea is that the impact energy is taken by ball bearing rollers on a pivot arm that transfers the energy into two shock absorbers. The movement of the absorbers is guided by a ball circulating carriage running on a linear rail. Ah yes, almost forgot, all the shiny parts should match in color:P

What‘s nice about Fusion 360, it has a catalog of standard parts that you can drop into your design. So you don’t have do design screws and the like. Once I received the parts orders in the mail, I printed the modeled parts for a test fit. The beauty of 3D printing came to my rescue more than once – it‘s super easy to make adjustments and cheap to re-print.

The springs gave me a bit of trouble. I could not get them to work properly even with varying the viscosities of the oil. The mess, the impatience and the fading motivation for the project eventually made me abandon the oil altogether. The impact of the door would not be as smooth as I had hoped, but okay.

The fridge door of the rented apartment was not mine to drill holes into, so double sided tape was the solution for fixation. Testing it for the first time, I proudly let go of the fridge door to let it cra… bounce into the kitchen door! Yay, it worked …for a couple of days. Then one night while falling asleep I heard a noise that I could not quite place but soon found out it had been the fridge damper hitting the floor. The double sided tape did not hold up to the challenge. Stronger tape fixed it.

Challenges & Learnings

- I often had the internal battle between „What the hell am I doing with my life?“ and „Easy peasy lemon squeezy, I can engineer every problem out of my life. And in addition everyone who gets to see my fridge will be so impressed“.

- I bought oil of different viscosities to see which would work best, none of them did. To my surprise the springs would completely seize up once filled with oil, no matter the viscosity. I remembered a Blitzer Beetle kit from Tamyia that I had built with my brother when we were kids which had working oil-filled dampers just like I had now. I got frustrated, lost patience and skipped the oil. So technically I ended up with springs only instead of a true spring-damper system.

- I learnt that double sided tape can seem like it can hold a rocket to the ground at launch but given some time still fails and then like a bored toddler drops your fridge damper on the floor.

Result

Ahhhh, it feels so nice not having to worry about breaking glass when you just want to check in on the yogurt. Whilst the damping effect was not as smooth as I had imagined (perhaps because of the true damping effect of the missing oil) but I had reached an acceptable state. Project: finished.

Reflections..

The project got me thinking about where I put my time and energy. Although the feeling of a finishing the project and seeing it work for the first time was great, I think the problem of fridge door handle vs glass is a small one in comparison and I could have lived with just some felt stuck to the handle.

Overengineering is fun and I see it as an exercise, but I think if anything is overengineered, it should be something of more relevance.

Resources

Have you tried something similar? Got tips or questions? Feel free to leave a comment below.

Leave a comment